Hybrid battery upgrades: converting a standard hybrid to plug-in

Can I convert a standard hybrid to plug-in (PHEV)?

Backyard mods for hybrids and EVs… Is this the next big thing in aftermarket tuning?

What could possibly go wrong?

So, you want to mod, hotrod, soup-up, trick-out and drop a stack on your EV or hybrid, so you can go burnin' up the quarter mile, coastin' through the heat lap trials. The chicks'll cream for grease lightnin'.

This question, from a dude whose parents had exquisite taste in child-naming, is one of the most fascinating I’ve had recently.

It’s opening the window to the next big thing in well-intentioned backyard disasters.

Tell me please, am I dreaming, or would it not be feasible, to convert a "soft hybrid" or just hybrid car to a full plug-in hybrid, by adding another battery and appropriate connections? Series or parallel, wouldn't that at least double autonomy and offer the option of mains charge? Or would it end up costing as much as a full EV?

- John

The disclaimer here - I’m a mechanical engineer, not an electrical engineer. So there’s every possibility some of the granular detail will elude me. But the broad brush-strokes are these:

Hypothetically, you could do this.

Contrary to popular belief, ‘anything’ is not possible, but this does exist in the domain of possibility.

But that does not mean it’s a great idea.

You’re talking about messing with a great deal of stored energy, and the potential for disaster is extremely high.

It’s a fascinating question, though, because as hybrids and EVs become more mainstream, I suspect we will see an explosion (hopefully not literally, at least, not all that often) an explosion in aftermarket modifications and kits for the electrical side of electrically motivated vehicles.

So, with the wick lit, let’s place the dynamite and answer Johnny Bravo’s question before he hurts himself.

Fat peg, small holes

Seeing as there’s no convenient, spare space in the engine bay or the sub-floor space (below the occupants in the cabin), the additional battery you fit would have to be installed in the boot, where it would be vulnerable to crash damage (which poses an extreme fire risk).

You’d have to include temperature management for both charging and discharging. (‘Discharge’ is the powertrain use, for motive power. Powering the electric motor.) If you don’t do this, there’s the risk of killing the battery early, and also fire or explosion. So, a cooling system is NOT OPTIONAL. (Looking at you, Nissan).

And, obviously, liquid cooling is the way to do it - it’s like, an order of magnitude more efficient than air cooling.

Then there’s the high-voltage wiring and all the technical caveats for safe installation that this imposes, and the sundry crap that you need - like a charging system and fittings. And the battery would have to be custom made, from individual cells, which would cost heaps - even as a DIY project; some might argue because it’s a DIY project.

I suppose you could find a wrecked plug-in hybrid - whatever, and salvage many of the bits.

Building connections

To put the battery bizzo in perspective, a 36-volt, 5 amp-hour battery for Ryobi yard-type electrical power tools costs $299 retail at Bunnings. And I’m sure they’re marking it right up, but at the same time they’re benefitting from mass production. That’s 180 watt-hours of electrical energy, or 0.18 kWh (kilowatt hours). Hold that thought.

“Help me, Ryobi-John, DIY battery mods are hopeless.”

-Princess Layman

A Hyundai Ioniq hybrid has 1.56 kWh of battery storage on board. (That’s about nine of these Ryobi batteries, equivalent.) I’m using the Ioniq as an example because the factory hybrid and plug-in hybrid executions are directly comparable - so you can see what a major carmaker has done in terms of each execution.

The plug-in hybrid Ioniq (same car - just plug-in) has 8.9 kWh of battery. (That’s about 50 of these Ryobi batteries.) It’s significant, right? Five and a half times more battery capacity.

Let’s say you intended - conservatively - to add 5 kWh of electrical storage to your standard hybrid ‘donor’ car. You have to find a spot for 30 of these batteries, near enough. At the same price per kilowatt-hour as the Ryobi battery that’s about (ballpark) 30 times the energy, so 30 times the price, or about $9000. Just for batteries like these, off the rack.

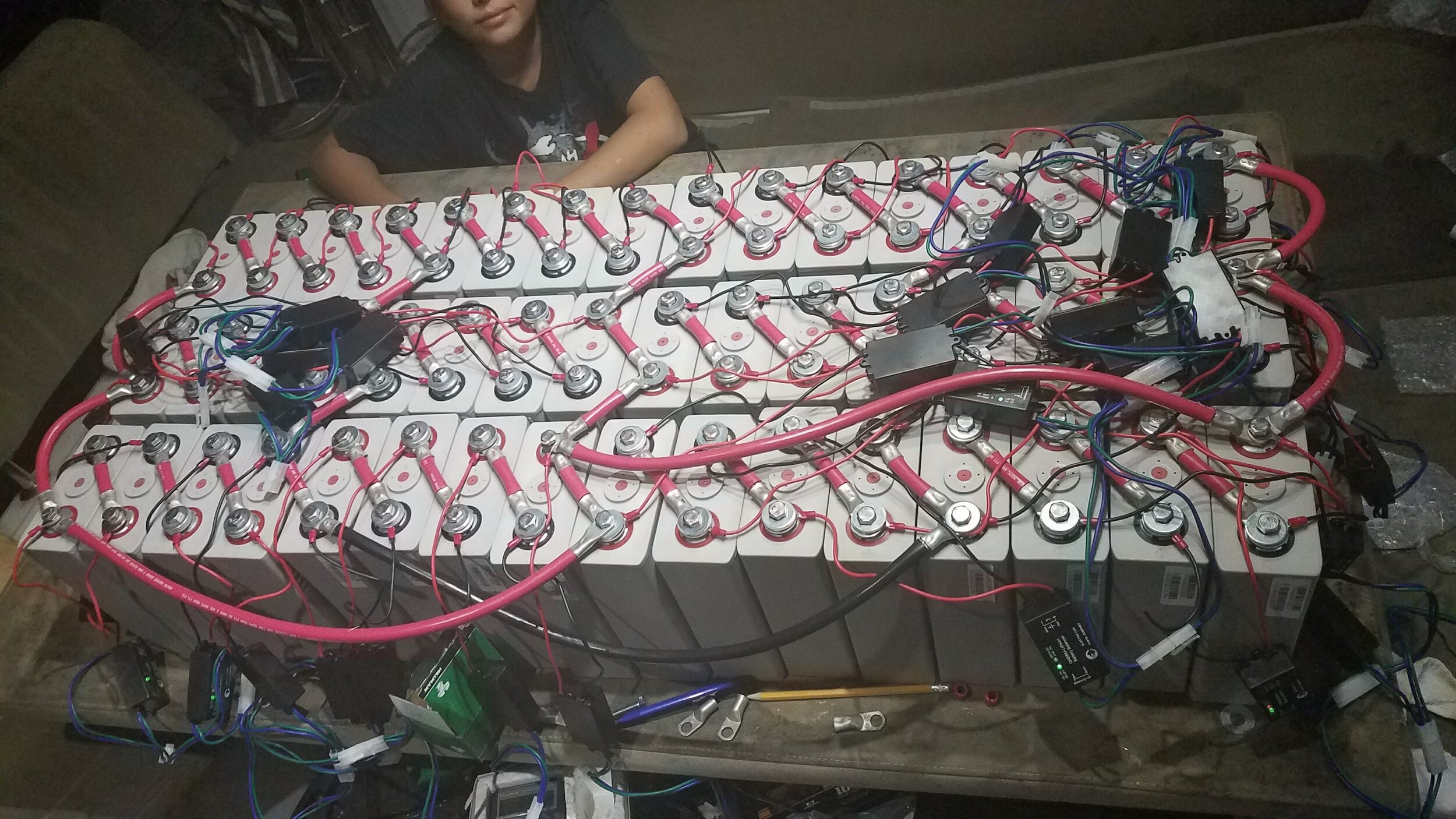

Jaycar Electronics here in Shitsville will sell you 18650-type Li-ion rechargeable battery cells (they’re unprotected cells) for $12.45 each as a bulk buy. They’re 9.62 Wh batteries. So you’d need 520 of them for 5 kWh - that’s about $6500.

And of course you’d need to figure out how to wire them up robustly and protect them against overcharging and discharging, and overheating… Which, in itself, is a serious engineering job. And you would want to get that right.

You’d probably buy the individual cells cheaper, from - I dunno - China. And if you do it from scratch, you really need a spot-welder to join them up. (Soldering is a bit ‘amateur’.) And you’d need a laser-cut wiring grid cut from - I dunno - stainless steel sheet, and a bunch of additional components such as a complete heat exchanger setup, mechanical damage containment enclosure, protection circuit, thermal overload protection, etc.

I’d buy a fire extinguisher, too. A big ‘fuck off’ one. I’m funny like that.

HEADING

It’s doubtful to me you could do this on a shoestring for less than about $20,000. That’s not including your own time. Bear in mind you can’t do development of this kind - properly, thoroughly - in one hit.

Nobody goes from ‘bright idea’ to ‘production-ready’ in one iteration. You’d need a prototype, then a second prototype incorporating a bunch of refinements from what you learned in prototype #1. Then - hopefully - you’d be production ready the third time. So make it $30,000 - if you want to do this right, and if you can successfully re-use a bunch of components from each of the previous prototypes, to save cost.

At this point it behooves me to point out that it’s cheaper just to buy the plug-in hybrid, which is about $6500 extra in the case of the Ioniq.

I also cannot overstate how just easy it is to hurt yourself badly if you get this wrong. Going from ‘nice idea’ to ‘patient in the burns unit’ is a foreseeable pathway for this driveway project to follow.

In choosing the donor car for this project you would also also need to ensure it could run, and provide adequate motive power across a wide range of driving conditions, just in ‘EV’ mode.

So bear in mind that the Ioniq plug-in has a 40 per cent more powerful electric motor to facilitate exactly this kind of more energetic EV mode of operation. Designing a bigger battery to drive a ‘Mr Puniverse’ electric motor would be another epic ‘own goal’. You might need an electric motor upgrade as well.

You’d also need to be able to hack the donor car’s software control architecture so that you avoided unpredictable feedback effects and operational conflicts - which are bound to occur with a modification that goes this deep.

Sidenote

I dunno if you saw it, but Hyundai built this ridiculous big blue bogan burnout bus - an iMax with the group’s big turbo V6 engine and eight-speed auto.

One of the biggest parts of that project, which they’ll probably hate me talking about, was solving exactly those kinds of software conflict issues - and they had full ‘plug and play’ operating system access.

So, your job hot-rodding the plug-in is going to be very difficult indeed, without manufacturer support, which you will not get.

Then you have to failsafe the installation … so that you don’t make the news in some spectacular ‘pyromaniacal’ fashion dropping Jimmy and Jemima off to daycare one morning.

Conclusive result?

If you are successful (doubtful) the resulting car is also going to be uninsurable - and you can’t just not tell your insurer you have done this because that’s a failure of your duty of disclosure, so you’ll pay the premium but be uninsured in any case…

This means: if you are a full-on electrical engineer with high-level electrical trade skills and you have access to a full-on prototype development workshop, with fire suppression, and a hard line to the burns unit, you’re not dreaming. Otherwise, you pretty much are. And even if you’re not dreaming, it’s going to be cost prohibitive.

So the only way I see this working is: some aftermarket brainiac has to do all the heavy lifting, overcome these hurdles, idiot-proof the whole thing and develop a kit that you (or an authorised installer) can jam into the right hybrid donor car.

And they’ll just have to get the numbers right to the extent that you can open your wallet and do the job for less than the cost of a brand-new plug-in hybrid from the carmaker. That’s a significant challenge - but I am absolutely certain aftermarket mods to EVs and hybrids are just around the corner. It’s gunna be interesting.

There are already plenty of wannabe carmakers with big ideas and a shed, but I’ll wager it’s only a matter of time before they get a whiff of that acrid, unmistakable smell of something burning - down there.

The Santa Fe offers a hybrid powertrain in one of Australia’s best-selling seven-seat SUVs, you get premium European-style refinement and the equipment you’d expect from prestige brands, keeping its value proposition and family appeal.