Three cylinders versus four: What’s the best engine for you?

In the market for a small-capacity new car? Can’t decide if three-cylinders are the in-thing or if four-cylinders are better? Let’s talk about that…

It’s the contender, slightly underweight but punching rooly rooly hard: the three-cylinder - versus - the naked pumping powerhouse, the champion in-line four.

This question is from a guy somewhat over-concerned about the proliferation of three-cylinder engines. Will they spread and take over, he wonders.

I have noticed 3 cylinder becoming all the rage in the small car market... Is this a cost cutting idea by the car manufacturers?

- Stuart

Okay, firstly, they’re not ‘all the rage’. There are just slightly more versions of an in-line three than there were back when dinosaurs roamed and I was in school etc. Inline four is still ‘all the rage’.

Three cylinder engines are often a cost-cutting measure, where they’re used for saving consumers money. And cost-cutting isn’t a negative thing, it’s often a benefit for customers because it means less cost passed onto you and it means the carmaker has a competitive edge against its competitors - presuming they pass on those savings. On the flip-side, adding costs often hurts you, the consumer.

Why manufacture four cylinders when three will do? If manufacturers have to bear any cost in R&D then the consumer has to pay, that’s how this work.

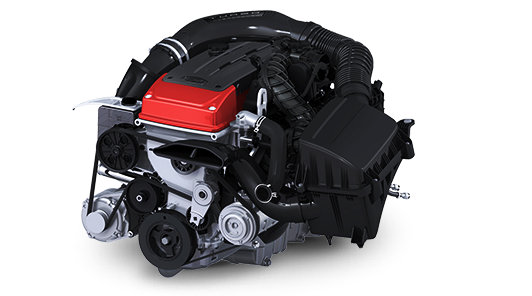

So, all these expensive technologies which have been developed like variable valve timing and CVVD, direct injection, turbocharging - what it does is increase the thermal efficiency of engines, allowing you to do more more with less capacity. And it inevitably means someone in R&D asking if they can drop an entire cylinder.

Increasing efficiency, doing more with less displacement, means you can reduce manufacturing costs, fewer lobes on camshafts to machine, fewer bearings to build, fewer crankshafts, the engine gets lighter, fuel economy improves, you can package it into a smaller engine bay.

All this reduction means less cost imposed on you and less taxing on the planet because each vehicle consumes fewer resources.

What manufacturers do is set basic parameters, targets to build a car that’s this big, with this fuel economy and so on. They start asking what their performance, economy and emissions.

Manufacturers start with targets so they can then figure out what technology they have in their inventory, what engines they have, asking how many cylinders do they need, what overall development costs can they already tick of without adding unnecessary costs. With a three-cylinder, you get optimal volume per cylinder which one of those starting advantages.

In-line of enquiry

Stuart’s Spanish inquisition continues…

Upcoming Toyota Yaris, Yaris cross, VW Polo etc are all using 3 cylinder motors. Are consumers better with a 3-cylinder over 4 cylinders?

- Stuart

This is the technical part of this report where we need to talk about the details between three and four cylinder engines.

So, before we start, let’s leave flat and horizontally opposed Boxer engines out of the conversation for now because that’s Subaru’s thing and they do that pretty well, with inherent advantages there. You can also tip an in-line four to one side (a slant-four), but that’s for another day.

Anyway, inline four-bangers. Pistons move vertically, in pairs, meaning Piston 1 moves up at the same time as Piston 4, (when Pistons 2 and 3 are coming down) which means perfect primary balance. Sounds awesome, but the flaw which needs to be compensated for in R&D is because of the geometry between the crank throw rotation and the conrod length. What happens is the pistons moving up are accelerating at a different rate than when they’re moving down, when above the centre line, compared to their corresponding motion below the centre line of the crankshaft.

It’s due to the geometry of the rod and the crank throw; there’s nothing that can be done about it and those forces imposed on the engine are unbalanced.

In what’s called ‘secondary balance’ the four-cylinder is poor. If you have a small reciprocating mass and capacity, those forces are small. But as you increase the capacity those forces become greater because they rotating mass is greater and beyond about 2.0 or 2.5-litre engines, you need need balance shafts. They compensate by rotating twice as fast as the crank to impose opposite forces to the intrinsic imbalance of that engine. That’s the inherent design deficiency of the four-cylinder engine which prevents it from being scaled right up - you don’t get big 16-litre four cylinder engines in trucks, for example, because it’s too hard to compensate for those forces, and it’s inefficient to make cylinders that big (we’ll get to that).

Three-cylinders though, have their crank pins at 120 degrees, so they have perfect primary and secondary balance - which is a distinct advantage over a four-cylinder engine. However, there’s another problem.

Because the combustion events are not symmetrical like in a four-cylinder, they cause the engine to rock longitudinally because you have three pistons moving up and down independently of each other. So there’s an inherent imbalance there to compensate for, or an undesirable operational characteristic.

In many ways, the in-line six-cylinder engine is the perfect engine because it’s just two in-line threes mirror-reversed and mounted together with a contiguous crankshaft. So you eliminate those longitudinal rocking forces because they’re compensated for; the front half balances out the back half and the rocking goes away. What it means is you can rev it really hard - anybody who’s driven a 1990s BMW M3, the 3.0-litre straight-six, knows what I’m talking about.

They essentially have no big rotational problems that need compensating for, so they can be scaled up for trucks etc. Three-cylinders, almost there, except for the rocking which needs fixing, and I’m not sure how necessary it is with very low-capacity engines; they might be able to get away with it using clever engine mounts to isolate the vibrations, which is much cheaper than inserting more metal.

Big emitters

Or is this a cheat by the car manufacturers to get past strict CO2 emissions?

- Stuart

We don’t have those strict emissions regulations. CO2 is intrinsic to combustion process, it cannot be circumvented by clever engineering, you cannot have a standard that demands X-emissions standard. Why?

When you burn X-kilograms of fuel, you get Y-kilograms of CO2. It’s science - that’s just how this works. It’s locked into a strict mathematical proportion. Legislation cannot just force chemistry to conform to a number. Doesn’t work like that.

In other markets like the US, they have corporate average fuel economy standards, which tells carmakers they must reduce their fuel economy to a certain number. Due to that strict CO2 proportionality of burning fuel, limiting consumption can equal CO2 and therefore you put a cap on emissions.

Here in ‘Straya, we don’t have a government enlightened enough to impose those corporate average standards or targets on manufacturers because, politicians are generally lawyers, and lawyers often don’t understand science. Also, they’re generally arseholes - so there’s that.

Instead we have strict limits on excessive emissions such as:

NOx (oxides of nitrogen, caused by running engines too lean - like Volkswagen),

CO (carbon monoxide, a deadly poison which replaces oxygen in the lungs, resulting from imperfect combustion),

Unburned hydrocarbons and PM2.5 for diesels)

The only hack for CO2 is hybrid. (Or just consume less). If combustion is complete, CO2 is the result - there’s no way to circumvent CO2 through technology having caused combustion.

Hybrid means you save 100% of the fuel you would have burned and the CO2 you would’ve created. Or you can just drive more gently, it’s really not that hard. You can also use your car more efficiently, do more on the same trip, rather than going back and forth repeatedly.

Engineering hack

I was looking at the up coming Toyota Yaris Cross but is a 1.5-litre, 3 cylinder. That doesn't excite me as I feel I’m loosing power and the car will be revving hard on hwy speeds.

What’s your thought on this up-coming trend?

- Stuart

Firstly, Stu, try harder to punctuate and for goodness sake, use spell checker. First impressions count. ‘Loosing’ is an easy way to fail a job application right there.

Now, if you’re in the market for automotive excitement and you’re shopping at House of Yaris, you’re entirely in the wrong boutique.

As much as they try hard to make their cars seem exciting, I routinely say Toyota is the King of Mediocrity. Beneath the skin they have the passion and soul of a tumble dryer - look elsewhere for true automotive thrill, Stu, because Yaris and Yaris Cross are not going to pull your pants down.

It doesn’t matter how many cylinders a car has, it’s about how it goes that is important. Does it meet your performance expectations? That’s what matters

If you’ve got a power-to-weight ratio greater than about 80kW/t, with decent mid-range torque and you don’t have to rev the engine’s tits off to make it perform - that’s a winner. If you’ve got 100kW/t, then you’ve got something seriously interesting.

People make all kinds of gross generalisations about cars with absolutely no rational thought behind it. They’ll say ‘Drum brakes on utes are shit’, and they’re really not - it depends how they’re executed. Or ‘leaf springs are shit’ or ‘multi-link rear suspension is shit’, but that’s not true, it just depends on how well that engineering has been done. It’s called Gestalt theory.

For a Yaris and Yaris Cross you want an engine that doesn’t need to rev its head off to reach peak power, and you want reasonable mid-range torque because you want it to perform okay when it’s not at its maximum output, around 2000-3000RPM.

Toyota says the Yaris Cross uses the Atkinson cycle (like the Kia Seltos >>), and the marketing brags about “40% thermal efficiency; greater than a diesel” - but what they’re not saying is that it hurts power.

The Atkinson cycle is a thermodynamics hack with an induction stroke which continues beyond bottom dead-centre, so as the piston starts to rise for compression, the inlet valve stays open briefly and pumps some of the air-fuel mixture out into the inlet manifold. Why?

When the valve closes and the piston is most of the way up the cylinder, as it completes the compression stroke, the spark plug fires and you get the expansional power stroke, the ratio of compression to the expansion is tweaked. You get greater expansion relative to the amount of compression, which gives rise to greater thermal efficiency.

But with the Atkinson cycle, what you’re doing is limiting the amount of air coming in per stroke, it limits the amount of fuel you can burn and therefore power production, because it’s tuned for economy, not performance.

Furthermore, there’s gonna be a hybrid Yaris Cross. It’ll be the 1.5-litre three-cylinder hybrid. Subject to the condition of the battery, it’ll give you performance off the mark, and it’ll improve economy somewhat in stop-start traffic, which is hybrid’s big trick.

And lastly, wait until it’s released in Australia because you’ll wanna check the fuel spec when it gets here - it might demand 95 RON (Like C-HR), because it’s ‘Designed & developed for Europe’.

If they don’t spend the money to tune the engine for 91RON fuel here, you’ll be buying a fairly unexciting but edgy-looking SUV which is economical - but it’ll demand premium unleaded. You’ll be spending more to save a little.

Don’t get caught by that little trap.